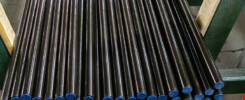

In industries where strength, corrosion resistance, and precision matter most, 4140 Chrome Hollow Rod emerges as a game-changing material solution. Engineered for demanding applications, our hollow rods combine the robustness of alloy steel with the elegant finish of chromium plating, delivering unmatched value to engineers, manufacturers, and OEMs.

Our 4140 Chrome Hollow Rod is designed to excel in high-performance scenarios:

Automotive Components: Piston rods, shock absorbers, and steering systems benefit from its fatigue resistance and dimensional stability.

Aerospace Hardware: Lightweight yet strong, it’s ideal for landing gear, hydraulic cylinders, and structural supports.

Industrial Machinery: Used in linear actuators, conveyor systems, and robotic arms where precision and longevity are critical.

Tool & Die Manufacturing: Perfect for molds, jigs, and fixtures requiring wear resistance and easy maintenance.

Marine & Offshore: Corrosion-resistant properties make it suitable for marine environments, including ship fittings and offshore drilling equipment.

Why choose 4140 Chrome Hollow Rod over conventional materials?

High-Grade Alloy Composition: 4140 steel features chromium (0.8-1.1%), molybdenum (0.15-0.25%), and vanadium (0.03-0.08%), delivering superior strength-to-weight ratio.

Lightweight Design: Hollow structure reduces weight by 30-50% compared to solid rods without compromising load-bearing capacity.

Corrosion Resistance: Chromium plating withstands harsh environments, including saltwater, chemicals, and extreme temperatures.

Vibration Damping: Internal damping properties minimize noise and wear in high-speed applications.

Cost-Effective Longevity: Reduced maintenance and replacement cycles lower long-term operational costs.