Hot Products

- Honed Tubes

- Skived & Roller Burnished Tube

- Hydraulic Cylinder Tube

- Chrome Plated Bar

- CK45 Chrome Plated Bar

- Chrome Plated Tubing

- Precision Cold Drawn Tube

- Induction Hardened Chrome Rod

- Hollow Chrome Rod

- 4140 Honed Cylinder Tube

- 4140 Hard Chrome Rod

- Stainless Steel Cylinder Tube

- Stainless Steel Cylinder Rod

- Deep Groove Ball Bearing

34CrMo4 Seamless Steel Tube

34CrMo/34CrMo4 Seamless Steel Tubes always be used on gas cylinder tubes,or important structural parts that work under high pressures, such as gas cylinder pipe ,transmission parts of vehicles and engines; Turbogenerator rotor, spindle, heavy load drive shaft, large section parts .

As one of the leading 34CrMo/34CrMo4 seamless tube suppliers and manufacturers,Wuxi YUTONG has been supplying and exporting 34CrMo4 seamless tube for almost 20 years with high quality & good prices.Imperial sizes & metric sizes available.

Overview of 34CRMO4 SEAMLESS STEEL TUBE

Description Of 34CrMo4 Seamless Steel Tube

Find Us Here

Address:

Yangshan Industrial Zone, Huishan Dist, Wuxi City, China.

E-Mail:

Tel & Wechat & Whatsapp:

+86-19921607440

Standards: GB18248 – 2000

OD: Φ50-325mm; wall thickness: 3-55mm;

OD tolerance: ±0.75%;

Wall margin: -10%—+12.5%

Transverse slope: ≤2mm;

Straightness: 1mm/1m;

Inside diameter roundness: no more than 80% of the OD diameter tolerance

Surface quality: without crack, folding, delamination and stammer

Product Categories: Seamless steel tubes for high pressure vessels

Usages: For all kinds of fuel, hydraulic, trailer, station with gas bottle

Steel Grade: 34CrMo4、 34CrMo 、30CrMo、34Mn2V、35CrMo、40CrMo 、 42Crmo 、 42Crmo4 、 37Mn、16Mn Surface

Process: cold drawn/cold rolled/Hot drawn/Hot rolled

Surface : Bared Black Painting, Galvanized,Coating

Package:Bundles, Bulk,PVC bags,Plywood case

BENEFITS OF 34CRMO/34CRMO4 SEAMLESS STEEL TUBE

Higher Strength & Hardness Properties

Size Accuracy

Enhanced Appearance

Uniform Micro-Structure

Easier To Machine

Tight tolerances, resulting in reduced machine time

Possible spiraling eccentricity inherent in product

WUXI YUTONG ALSO SUPPLY THE FOLLOWING TUBES AND RODS

4140 Honed Cylinder Barrel/Tube

Stainless Steel Honed Tubing

Cylinder Honed Tubing

Precision Cold Drawn Seamless Tube

Hollow Chrome Rod/Induction Hardened Chrome Rod

As a professional steel tubes and rods supplier, manufacturer,exporter in China, Wuxi YUTONG has more than 20 years production experience, we supply to customers and provide full range of technical support.

Imperial sizes & metric sizes & special size all available.

100% Quality assurance

100% Customers repurchase

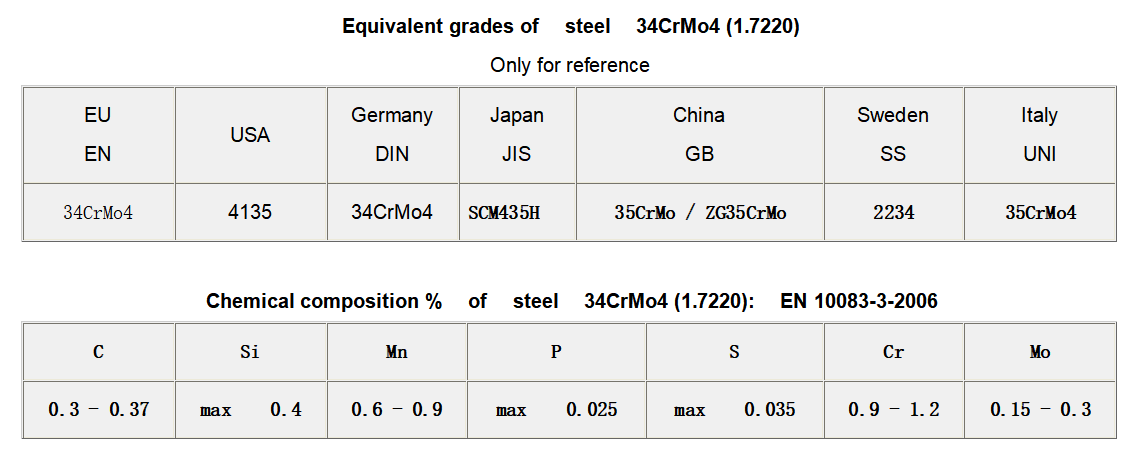

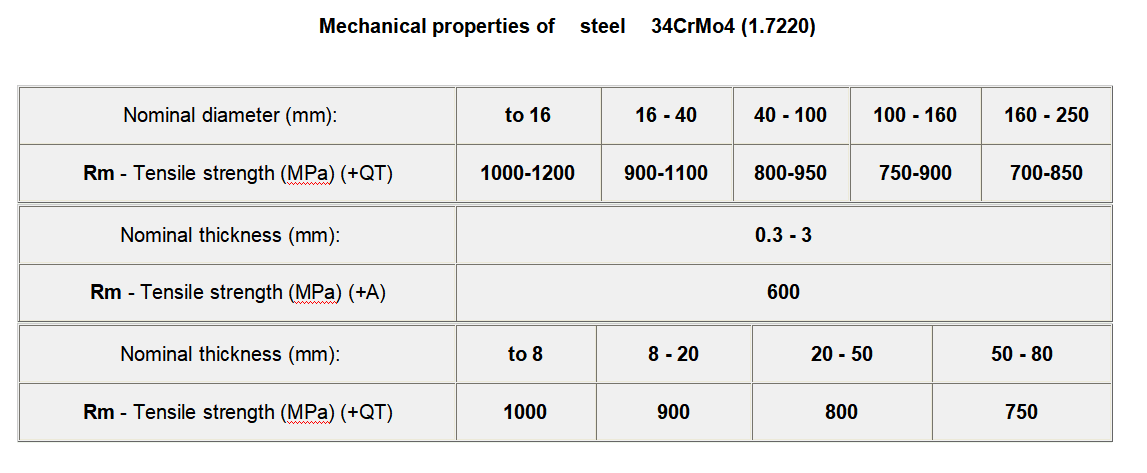

Below is the chemical composition & mechanical properties of the main steel grades for 34CrMo4 seamless steel tube.

- Superior surface finish

- High yield strength

- Dimensional accuracy and excellent micro-structure uniformity

- Enhanced machinability

- High strength to weight ratio

- Tight tolerances, resulting in reduced machine time

- Possible spiraling eccentricity inherent in product

- Flexible order quantity: we accept small quantity orders, even if there is only one piece of hydraulic cylinder tubing we can produce and supply.

- Good weld ability: The weld ability of our honed steel tubing is very good, this is quite helpful for manufacturing the cylinders.

1.Extensive production experience: more than 20 years manufacturing experience for honed tube and chrome plated rod, in Australia, Peru, Chile, Thailand, Singapore,Columbia,Canada, Mexico,US,Saudi Arabia,Brazil, India, Iran, Indonesia and other countries have long-term buyers.

2.Advanced production equipment: cold drawing machine, honing machine, skiving & roller burnishing machine, straightening machine, polishing machine, heat treatment furnace, grinding machine, etc. We have professional technicians do regular scheduled maintenance on these machines to guarantee them work well.

3.High quality raw material: our raw material mainly from some famous steel mills, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

4.High precision: Honed Tube, inside surface roughness 02-0.4 um, straightness max 0.5/1000, strict tolerance DIN2391 H8. Skived & Roller Burnished Tube, inside surface roughness under 0.2 um, straightness max 0.2/1000, strict tolerance DIN2391 H8. Chrome Plated Rod, chrome layer 10 micron to 100 micron, strict tolerance ISO f7.

5.Strict quality control: we have professional in-house QC to inspect all products. We will do Chemical Composition Test, Mechanical Property Test, Dimension Inspect, Roughness Test, Chrome Layer Test and other tests in need before delivery.

6.Safe packing: an-rust oil on tubes and rods before delivery. Plastic caps on both ends to protect tube inside surface. Then be packed with seaworthy package or in wooden case.

READY TO START A PROJECT?WORK WITH US!

REQUEST FOR QUOTE

Services

7

Contact : Mr Jack

Email: sales@cylinder-bar.com / info@cylinder-bar.com

Mobile & Whatsapp& Wechat :+86-19921607440