Hot Products

- Honed Tubes

- Skived & Roller Burnished Tube

- Hydraulic Cylinder Tube

- Chrome Plated Bar

- CK45 Chrome Plated Bar

- Chrome Plated Tubing

- Precision Cold Drawn Tube

- Induction Hardened Chrome Rod

- Hollow Chrome Rod

- 4140 Honed Cylinder Tube

- 4140 Hard Chrome Rod

- Stainless Steel Cylinder Tube

- Stainless Steel Cylinder Rod

- Deep Groove Ball Bearing

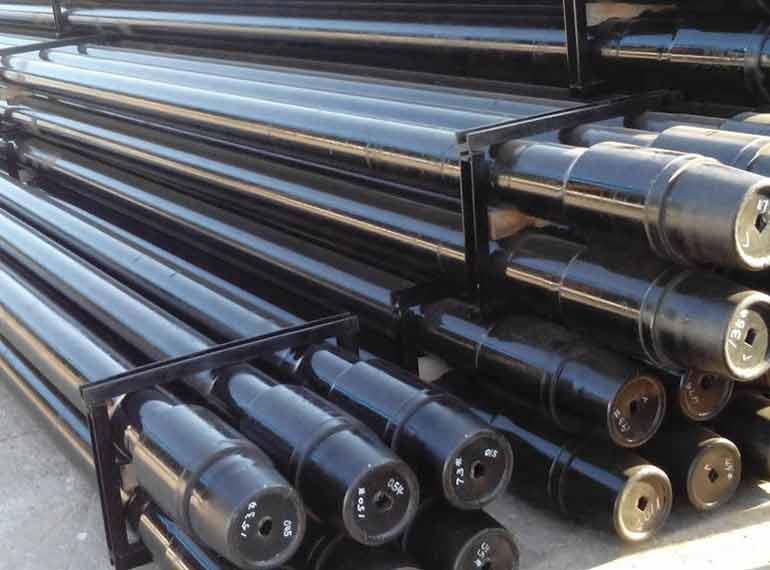

Oil Drill Pipe

Oil drill pipe is a type of steel pipeline with screw thread in the pipe end. It is utilized for linking ground rig devices and drill grinding equipment at the bottom of drilling wells. The main function of drill pipes is to transfer drilling mud to the drill bit.

As one of the leading oil drill pipe suppliers and manufacturers,Wuxi YUTONG supplies a variety of drill pipelines readily available in different sizes and weights to satisfy the drilling requirements of business in the oil and gas market.

Description Of Oil Drill Pipe

Material: API 5DP, ST52,CK45,SAE4140,SAE4130,SS304,SS316

Heat treatment: multi-point temperature measurement to guarantee perfect match between strength and toughness.

Nitrogen Process: only one manufacturer to use surface nitrogening on the whole drill rod, except longer the working life of thread, but also extend the service time for the body part.

Quality controll: All the processes during manufacturing.

Manufacture Model: Forged and Friction welding rod.

Compatible Brand: Vermeer, Case, Ditch Witch and other Chinese models.

Protection: Anti-rust oil on inside and outside surface, plastic caps in both ends.

Packing: Bundle with steel strip and PE sheet or wooden case

Overview of our Precision Cold Drawn Seamless Tube

Find Us Here

Address:

Yangshan Industrial Zone, Huishan Dist, Wuxi City, China.

E-Mail:

Tel & Wechat & Whatsapp:

+86-19921607440

Manufacturing technique:

1. Process: EAF + LF + VD + Forged + Heat Treatment (optional)+Fine machined

2. Heat treatment: Normalized / Annealed / Quenched / tempered

3. Delivery condition: Hot forged +Rough machined +Turned (optional)+fined machined

Test: UT & MT testing

1.Our drill pipes are mainly made from 4330V forging steel.

2.The physical properties are guaranteed one inch below the surface at normal temperature.

3.Heat treated by water quenching and tempering,rough machined as the drawing dimensions.

4.Strict UT inspection according to ASTM A-388 to guarantee high quality.

5. Tungsten Carbide alloy buttons were inserted into blades so as to keep its hardness.

WUXI YUTONG ALSO SUPPLY THE FOLLOWING TUBES AND RODS

4140 Honed Cylinder Barrel/Tube

Stainless Steel Honed Tubing

Cylinder Honed Tubing

Precision Cold Drawn Seamless Tube

Hollow Chrome Rod/Induction Hardened Chrome Rod

As a professional precision cold drawn tube supplier, manufacturer,exporter in China, Wuxi YUTONG has more than 20 years production experience, we sell cold drawn seamless tube and hydraulic honed tubing to customers and provide full range of technical support.

-

Imperial sizes & metric sizes & special size all available.

-

100% Quality assurance

-

100% Customers repurchase

1.Extensive production experience: more than 20 years manufacturing experience for honed tube and chrome plated rod, in Australia, Peru, Chile, Thailand, Singapore,Columbia,Canada, Mexico,US,Saudi Arabia,Brazil, India, Iran, Indonesia and other countries have long-term buyers.

2.Advanced production equipment: cold drawing machine, honing machine, skiving & roller burnishing machine, straightening machine, polishing machine, heat treatment furnace, grinding machine, etc. We have professional technicians do regular scheduled maintenance on these machines to guarantee them work well.

3.High quality raw material: our raw material mainly from some famous steel mills, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

4.High precision: Honed Tube, inside surface roughness 02-0.4 um, straightness max 0.5/1000, strict tolerance DIN2391 H8. Skived & Roller Burnished Tube, inside surface roughness under 0.2 um, straightness max 0.2/1000, strict tolerance DIN2391 H8. Chrome Plated Rod, chrome layer 10 micron to 100 micron, strict tolerance ISO f7.

5.Strict quality control: we have professional in-house QC to inspect all products. We will do Chemical Composition Test, Mechanical Property Test, Dimension Inspect, Roughness Test, Chrome Layer Test and other tests in need before delivery.

6.Safe packing: an-rust oil on tubes and rods before delivery. Plastic caps on both ends to protect tube inside surface. Then be packed with seaworthy package or in wooden case.

READY TO START A PROJECT?WORK WITH US!

REQUEST FOR QUOTE

Services

7

Contact : Mr Jack

Email: sales@cylinder-bar.com / info@cylinder-bar.com

Mobile & Whatsapp& Wechat :+86-19921607440